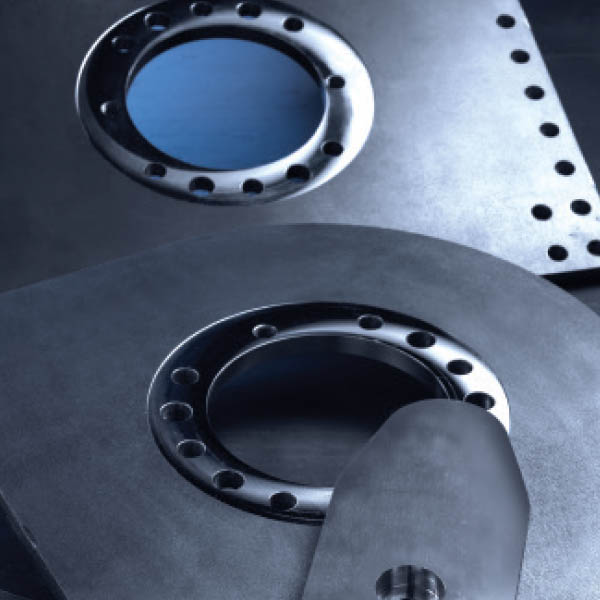

Machining, Drilling, and Beveling

Top Quality Beveling, Drilling, and Machining Services

Each year, our customers trust us to drill millions of inches in hole depth to their exact specifications. Our high-capacity machining centers make the difference. Like all of our modern equipment, they are expertly operated by Port City employees who understand your need for quality, on-time results.

Technically Advanced Machining, Drilling, and Beveling Equipment

Port City Metal Services' CNC VERTICAL MACHINING CENTERS feature work envelopes ranging from 20” x 40” to 90” x 207”. All units are equipped with automatic tool changers, high pressure, thru-the-spindle coolant, Renishaw probes, and many have dual pallets for maximum throughput. Our CNC HORIZONTAL, MULTI-PALLET MACHINING CENTER has automatic tool changers, high pressure, thru-the-spindle coolant, and Renishaw probes. We also have MILLING BEVELING MACHINES with up to 200” long capacity.

MODEL SIZE TOOLS HORSEPOWER

2019 Mazak Palletech HCN-6800 38" x 38" 10 pallets 120 tools 50 HP @ 8000 RPM

2019 Mazak VTC 805G 23.5" x 117" single pallet 40 tools 40 HP @ 6000 RPM

2014 Quickmill Annihilator 91" x 207" single pallet 20 tools 35 HP @ 6000 RPM

2014 Mazak 510C / 50-II 18" x 39" dual pallet 24 tools 30 HP @ 6000 RPM

2013 Mazak 510C / 50-II 18" x 39" dual pallet 24 tools 30 HP @ 6000 RPM

2011 Mazak FJV 60/160 46" x 155" dual pallet 40 tools 35 HP @ 6000 RPM

2009 Mazak FJV 60/160 46" X 155" dual pallet 40 tools 35 HP @ 6000 RPM

2006 Mazak FJV 50/80 36" x 76" dual pallet 40 tools 35 HP @ 6000 RPM

2005 Okuma 650 VB 24" x 57" single pallet 32 tools 30 HP @ 6000 RPM

2005 Rockford Bevel Machine 17' table length 1 tool 30 HP

2004 Mazak FJV 50/80 36" x 76" dual pallet 40 tools 35 HP @ 6000 RPM

MATERIAL TYPES:

- Carbon Steels

- Stainless Steels